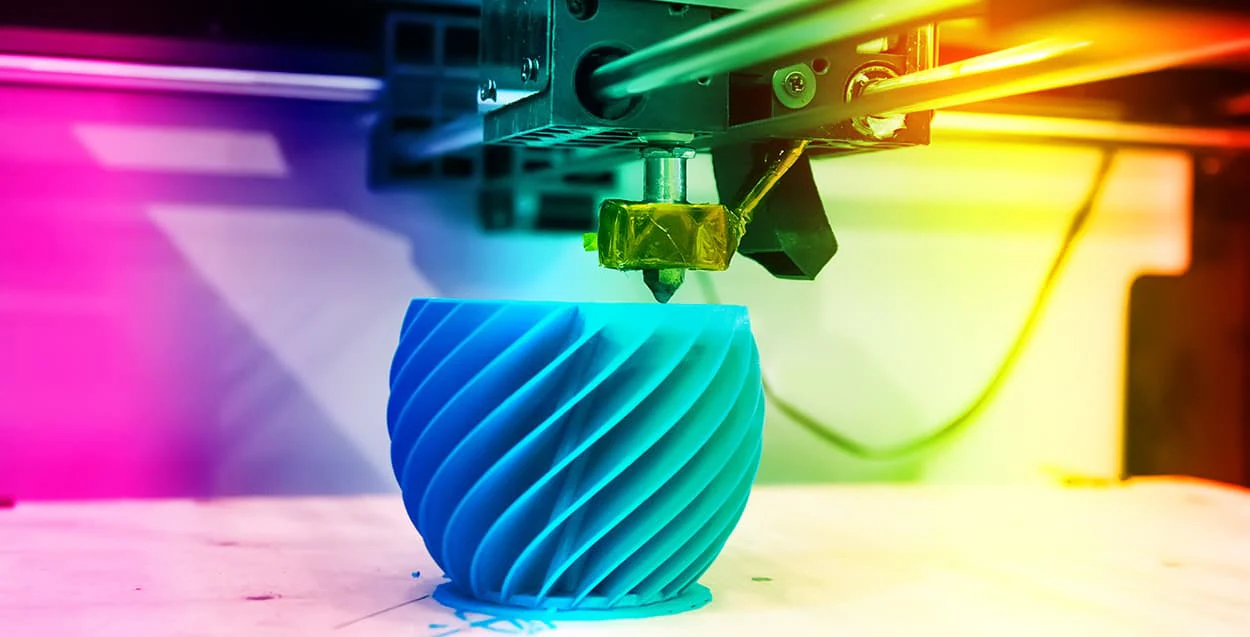

In the fast-evolving landscape of manufacturing, Robotic 3D printing is emerging as a transformative technology that holds the potential to significantly speed up production. This innovation, powered by advanced 3D printers, integrates robotics with traditional 3D printing processes to deliver unprecedented efficiency, precision, and scalability.

How Robotic 3D Printing Works

At its core, Robotic 3D printing combines the dexterity of robotics with the layer-by-layer precision of 3D printing. By using robotic arms, manufacturers can automate complex print jobs that previously required human intervention. These robotic systems can perform tasks such as material handling, quality control, and post-processing, allowing for a continuous, streamlined workflow.

The result? Enhanced efficiency that reduces time spent on manual adjustments, increases accuracy, and ultimately speeds up production. Additionally, robots are capable of working around the clock, further boosting productivity by eliminating the need for breaks or shift changes.

Advantages of Robotic 3D Printing

One of the most notable advantages of Robotic 3D printing is its ability to speed up production while maintaining high-quality output. Here’s how:

- Increased Automation: With robotic arms handling the heavy lifting, manufacturers can automate time-consuming tasks such as loading and unloading the printer, changing materials, and performing routine maintenance. This automation reduces downtime and enables continuous production.

- Scalability: Traditional 3D printers are often limited by size and complexity. However, Robotic 3D printing systems can scale up easily, handling larger print volumes and more intricate designs without sacrificing speed. This scalability is crucial for industries like aerospace, automotive, and construction, where rapid prototyping and large-scale production are essential.

- Precision and Consistency: Robots bring a level of precision that minimizes errors, ensuring each printed object meets exact specifications. This consistency is particularly important in industries where safety and reliability are paramount, such as healthcare and engineering.

- Material Versatility: Robotic 3D printers can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to use the best material for each job, optimizing production speed and product durability.

Applications Across Industries

The ability to speed up production has made Robotic 3D printing an attractive option across multiple industries. In the construction sector, for example, robotic arms can print entire buildings, significantly reducing labor costs and construction times. In aerospace, lightweight, high-strength components can be rapidly produced, cutting down the time required for prototyping and testing.

Robotic 3D Printing vs. Ordinary 3D Printing: A Comparative Analysis

Robotic 3D printing represents an innovative evolution of conventional 3D printing, transforming how objects are manufactured by integrating robotics to further speed up production. While both methods share the foundational principle of additive manufacturing, there are key differences between Robotic 3D printing and “ordinary” 3D printers that set them apart in terms of automation, scalability, and efficiency.

Key Differences Between Robotic 3D Printing and Ordinary 3D Printing

- Automation Level

Ordinary 3D printing involves standard 3D printers that typically require manual intervention for tasks like material handling, printer setup, and part removal. Even though these systems are efficient, they often need periodic human oversight, slowing down the overall workflow.In contrast, Robotic 3D printing integrates robotics into the printing process, automating much of the manual work. Robotic arms can load and unload materials, monitor print progress, and even handle post-processing tasks without the need for human involvement. This high level of automation significantly speeds up production, allowing continuous operation with minimal downtime. - Precision and Flexibility

Ordinary 3D printers deliver precise results but can be limited in terms of flexibility and the size of objects they can print. Larger, more complex objects often require multiple printing stages or the use of multiple machines, which can delay the production cycle.Robotic 3D printing, however, offers increased precision and flexibility through the use of robotic arms. These robotic systems can move freely in multiple axes, expanding the design possibilities beyond the limitations of traditional printers. As a result, larger and more intricate objects can be produced faster and with fewer interruptions, contributing to a speed-up in production. - Scalability and Production Volume

Ordinary 3D printers are typically used for small-scale production, rapid prototyping, or producing custom, low-volume items. While they are ideal for these tasks, scaling up production for mass manufacturing can be a challenge due to size constraints and the need for operator supervision.In contrast, Robotic 3D printing is highly scalable, making it better suited for large-scale manufacturing. Robotic systems can manage multiple 3D printers at once or print larger components in a single run, significantly increasing production volume. This scalability is particularly beneficial for industries that require mass production of complex parts, such as aerospace and automotive sectors. - Material Handling and Versatility

While ordinary 3D printers are often limited to specific types of materials depending on the model, Robotic 3D printing systems can handle a wider variety of materials, from metals to advanced composites. This versatility enhances production efficiency by allowing manufacturers to use the best material for the task at hand without having to switch between different machines or processes.The ability of robots to switch materials autonomously further speeds up production by eliminating manual changes and reducing setup times. This leads to a faster, more flexible manufacturing process. - Production Speed

Both ordinary 3D printing and Robotic 3D printing can produce high-quality parts, but Robotic 3D printing offers a distinct advantage when it comes to speeding up production. The robotic system can operate continuously, around the clock, while also performing multiple tasks simultaneously. This results in faster turnaround times compared to traditional 3D printers, which may require frequent pauses for maintenance, manual adjustments, or material changes.Moreover, robots in Robotic 3D printing can optimize the print path and minimize waste, further enhancing production speed and reducing material costs.In conclusion, Robotic 3D printing is revolutionizing the manufacturing world by speeding up production processes, improving accuracy, and offering scalable solutions for complex tasks. As industries continue to embrace this technology, the potential for faster, more efficient production will only grow, making it a cornerstone of modern manufacturing.